TCH.1C-27J-2-29JG

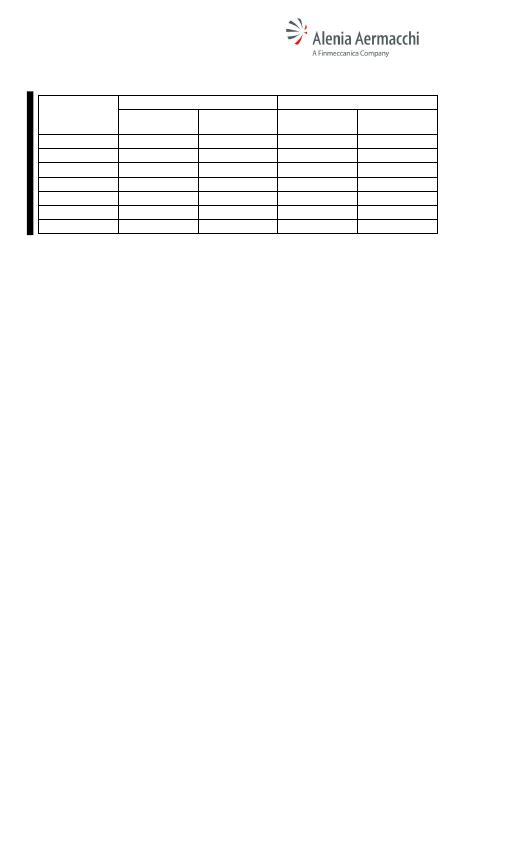

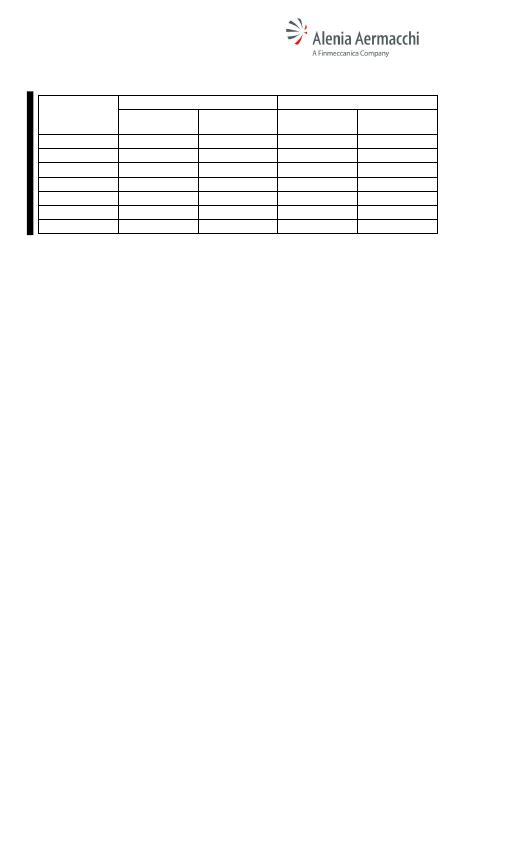

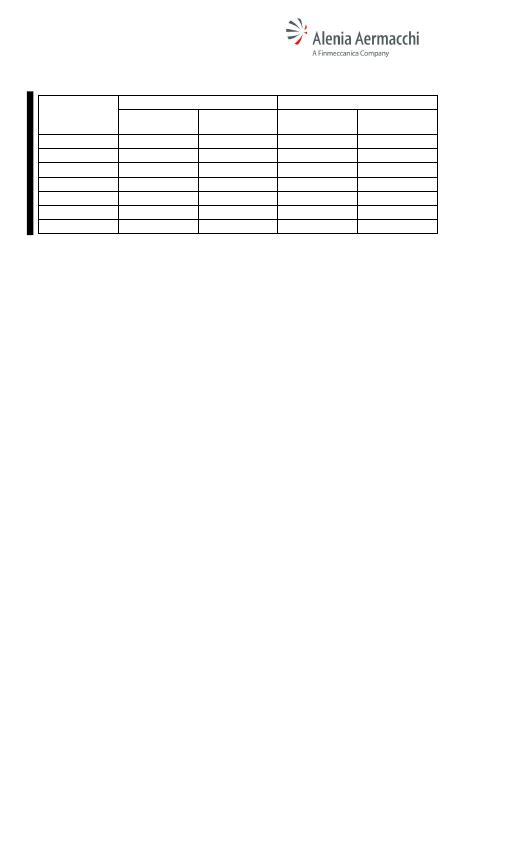

Table 2-2. Swage tools

FITTING SIZE

TUBE O.D.

FOR10000 psig PUMP "DTL Series"

inch.

mm

SWAGE HEAD

ASSEMBLY

POWER UNIT

-4

1/4

6.35

DLT05PSHA3004 DLT05MAPW000

-5

5/16

7.94

DLT10PSHA3005 DLT10MAPW000

-6

3/8

9.52

DLT10PSHA3006 DLT10MAPW000

-8

1/2

12.70

DLT20PSHA3008 DLT20MAPW000

-10

5/8

15.88

DLT20PSHA3010 DLT20MAPW000

-12

3/4

19.5

DLT30PSHA3012 DLT30MAPW000

-16

1

25.40

DLT40PSHA3016 DLT40MAPW000

2-3.3

TUBING REPAIR PROCEDURES (refer to figure

1.Three basic types of tubing system failures lend

themselves to permanent repair using

PERMASWAGE techniques. The failure types and

recommended repair procedures are the follows:

A.TYPE 1: small hole or short crack in tube

(a)Make one or two cuts as necessary to allow

removal of damaged tube section (if two cuts

are required and the distance between cuts

exceeds 0.299 in (7.6 mm), use repair TYPE 2).

Make cuts only after checking to make sure

enough space in which to operate swage tool.

(b)Replace removed section of tube with a

compatible PERMASWAGE union fitting.

B.TYPE 2: lengthwise crack in tube (crack longer

than 0.299 in (7.6 mm))

(a)Make two cuts to allow removal of damaged

section of tube. Make cuts only after checking

to make sure enough space in which to operate

swage tool.

(Cont'd)

29-00-20

2-12